Non-Permitted Explosives

Superpower 90 packaged emulsion explosive is a robust, high strength, detonator sensitive explosive. The explosive is having a firm putty-like consistency. Products are sensitized through chemical gassing / micro-spheres / combination of both. It is a water resistant packaged explosive.

Superpower 90 is designed for priming applications and as a column explosive in surface and underground mining and general blasting. The high detonation velocity and the robust nature of Superpower 90 make it an ideal primer for the initiation of column charge.

| Nominal Density (g/cc) | 1.20 ± 0.05 |

| Relative Weight Strength* | 118 % |

| Relative Bulk Strength* | 166 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Superpower 90 is packaged in plastic film with product name & other details. Each Box contains 25kg of product.

| Cartridge Dia mm |

Nominal length mm |

Nominal Wt. gm |

Cartridge/Box No’s. |

| 25 | 200 | 125 | 200 |

| 32 | 200 | 200 | 125 |

| 40 | 300 | 390 | 64 |

| 50 | 240 | 500 | 50 |

| 50 | 450 | 1000 | 25 |

| 60 | 460 | 1560 | 16 |

| 80 | 480 | 2780 | 9 |

| 90 | 420 | 2780 | 9 |

Other diameter / grams combinations can be offered on request.

Not suitable for ground containing reactive Sulphides.

Suitable for use in ground temperatures up to 65ºC.

In case application requires to operate outside this temperature range, please contact your Solar representative.

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present. Even with full length slitting of cartridges, the explosive will give good performance after two weeks immersion.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Superpower 90 is 12 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate pre-maturely.

Authorised Name of Explosive : SUPERPOWER 90

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Superpower 80 packaged emulsion explosive is a robust, high strength, detonator sensitive explosive. The explosive is having a firm putty-like consistency. Products are sensitized through chemical gassing / micro-spheres / combination of both. It is a water resistant packaged explosive.

Superpower 80 is designed for priming applications and as a column explosive in surface and underground mining and general blasting. The high detonation velocity and the robust nature of Superpower 80 make it an ideal primer for the initiation of column charge.

| Nominal Density (g/cc) | 1.20 ± 0.05 |

| Relative Weight Strength* | 100 % |

| Relative Bulk Strength* | 140 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Superpower 80 is packaged in plastic film with product name & other details. Each Box contains 25kg of product.

| Cartridge Dia mm |

Nominal length mm |

Nominal Wt. gm |

Cartridge/Box No’s. |

| 25 | 200 | 125 | 200 |

| 32 | 200 | 200 | 125 |

| 40 | 300 | 390 | 64 |

| 50 | 240 | 500 | 50 |

| 50 | 450 | 1000 | 25 |

| 60 | 460 | 1560 | 16 |

| 80 | 480 | 2780 | 9 |

| 90 | 420 | 2780 | 9 |

Other diameter / grams combinations can be offered on request.

Not suitable for ground containing reactive Sulphides.

Suitable for use in ground temperatures up to 65ºC.

In case application requires to operate outside this temperature range, please contact your Solar representative.

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present. Even with full length slitting of cartridges, the explosive will give good performance after two weeks immersion.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Superpower 80 is 12 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate pre-maturely.

Authorised Name of Explosive : SUPERPOWER 80

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Solarprime is a high strength cap sensitive packaged slurry explosives suitable for use in most types of blasting applications using small, medium and large diameter holes and represent the latest development in slurry explosives technology.

The product is chemically gassed and then cross-linked and is specifically designed for blasts in open cut mines, quarries and construction. Superior rigid gel also ensures good handling.

Its high strength and high velocity of detonation ensures good fragmentation in hard strata and give excellent blast results in quarrying, road cutting, canal excavation and civil construction.

Product is relatively insensitive to accidental initiation due to impact, friction and fire. Hence it is very safe during handling, transportation, storage and usage.

Excellent water resistance allows usage in watery holes. Product has excellent fume characteristics post detonation.

| Nominal Density (g/cc) | 1.20 ± 0.05 |

| Relative Weight Strength* | 85 % |

| Relative Bulk Strength* | 110 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Solarprime is packaged in plastic film / layflats. Each box contains nominally 25kg of product with standard cartridge sizes and counts as follows :

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 83 | 460 | 2780 | 9 |

| 125 | 460 | 6250 | 4 |

Other diameter / grams combinations can be offered on request.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Solarprime is 6 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate pre-maturely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SOLARPRIME

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Solar Gel is a high strength booster sensitive packaged emulsion explosives suitable for use in most types of blasting applications using small, medium and large diameter holes and represent the latest development in slurry explosives technology.

The product is chemically gassed and is specifically designed for blasts in open cut mines, quarries and construction. Superior rigid gel also ensures good handling.

Its high strength and high velocity of detonation ensures good fragmentation in hard strata and give excellent blast results in quarrying, road cutting, canal excavation and civil construction.

Product is relatively insensitive to accidental initiation due to impact, friction and fire. Hence it is very safe during handling, transportation, storage and usage.

Excellent water resistance allows usage in watery holes. Product has excellent fume characteristics post detonation.

| Nominal Density (g/cc) | 1.20 ± 0.05 |

| Relative Weight Strength* | 75 % |

| Relative Bulk Strength* | 100 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Solar Gel is packaged in plastic film/layflats. Each box contains nominally 25kg of product with standard cartridge sizes and counts as follows :

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 83 | 460 | 2780 | 9 |

| 125 | 460 | 6250 | 4 |

Other diameter / grams combinations can be offered on request.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Solar Gel is 6 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate pre-maturely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SOLAR GEL

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Solar Gel-E is a high strength booster sensitive packaged explosives suitable for use in most types of blasting applications using small, medium and large diameter holes and represent the latest development in slurry explosives technology.

The product is chemically gassed and is specifically designed for blasts in open cut mines, quarries and construction. Superior rigid gel also ensures good handling.

Its high strength and high velocity of detonation ensures good fragmentation in hard strata and give excellent blast results in quarrying, road cutting, canal excavation and civil construction.

Product is relatively insensitive to accidental initiation due to impact, friction and fire. Hence it is very safe during handling, transportation, storage and usage.

Excellent water resistance allows usage in watery holes. Product has excellent fume characteristics post detonation.

| Nominal Density (g/cc) | 1.15 ± 0.05 |

| Relative Weight Strength* | 82 % |

| Relative Bulk Strength* | 100 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.8 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Solar Gel-E is packaged in plastic film/layflats. Each box contains nominally 25kg of product with standard

cartridge sizes and counts as follows :

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 83 | 460 | 2780 | 9 |

| 125 | 460 | 6250 | 4 |

Other diameter / grams combinations can be offered on request.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Solar Gel-E is 6 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate prematurely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SOLAR GEL-E

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Solar Prime-E is a high strength cap sensitive packaged slurry explosives suitable for use in most types of blasting applications using small, medium and large diameter holes and represent the latest development in slurry explosives technology.

The product is chemically gassed and then cross-linked and is specifically designed for blasts in open cut mines, quarries and construction. Superior rigid gel also ensures good handling.

Its high strength and high velocity of detonation ensures good fragmentation in hard strata and give excellent blast results in quarrying, road cutting, canal excavation and civil construction.

Product is relatively insensitive to accidental initiation due to impact, friction and fire. Hence it is very safe during handling, transportation, storage and usage.

Excellent water resistance allows usage in watery holes. Product has excellent fume characteristics post Detonation.

| Nominal Density (g/cc) | 1.15 ± 0.05 |

| Relative Weight Strength* | 88 % |

| Relative Bulk Strength* | 125 % |

| Minimum Velocity of Detonation (Km/Sec) | 4.0 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Solarprime-E is packaged in plastic film / layflats. Each box contains nominally 25kg of product with standard cartridge sizes and counts as follows :

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 83 | 460 | 2780 | 9 |

| 125 | 460 | 6250 | 4 |

Other diameter / grams combinations can be offered on request.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Solar Prime-E is 6 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate prematurely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SOLARPRIME-E

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Superpower Gold packaged emulsion explosive is a robust, high strength, detonator sensitive explosive. The explosive is having a firm putty-like consistency. Products are sensitized through chemical gassing / micro-spheres / combination of both. It is a water resistant packaged explosive.

Superpower Gold is designed for priming applications and as a column explosive in surface and underground mining and general blasting. The high detonation velocity and the robust nature of Superpower Gold make it an ideal primer for the initiation of column charge.

| Nominal Density (g/cc) | 1.20 ± 0.05 |

| Relative Weight Strength* | 126 % |

| Relative Bulk Strength* | 178 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 |

*Compared to ANFO@ 0.85 g/cc

Notes :

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.30 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Superpower Gold is packaged in plastic film with product name & other details. Each Box contains 25kg of product.

| Cartridge Dia mm |

Nominal length mm |

Nominal length gm |

Cartridge/Box No’s. |

| 25 | 200 | 125 | 200 |

| 32 | 200 | 200 | 125 |

| 40 | 300 | 390 | 64 |

| 50 | 240 | 500 | 50 |

| 50 | 450 | 1000 | 25 |

| 60 | 460 | 1560 | 16 |

| 80 | 480 | 2780 | 9 |

| 90 | 420 | 2780 | 9 |

Other diameter / grams combinations can be offered on request.

Not suitable for ground containing reactive Sulphides.

Suitable for use in ground temperatures up to 65ºC.

In case application requires to operate outside this temperature range, please contact your Solar representative.

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present. Even with full length slitting of cartridges, the explosive will give good performance after two weeks immersion.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Superpower Gold is 12 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate prematurely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SUPERPOWER GOLD

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Solarprime MaxX is a high strength cap sensitive packaged slurry explosives suitable for use in most

types of blasting applications using small, medium and large diameter holes and represent the latest development in slurry explosives technology.

The product is chemically gassed and then cross-linked and is specifically designed for blasts in open cut mines, quarries and construction. Superior rigid gel also Insures good handling.

Its high strength and high velocity of detonation ensures good fragmentation in hard strata and give excellent blast results in quarrying, road cutting, canal excavation and civil construction.

Product is relatively insensitive to accidental initiation due to impact, friction and fire. Hence it is very safe during handling, transportation, storage and usage.

Product has excellent fume characteristics post detonation.

| Nominal Density (g/cc) | 1.00 ± 0.05 |

| Relative Weight Strength* | 80 % |

| Relative Bulk Strength* | 110 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.8 |

*Compared to ANFO@ 0.85 g/cc

1. REE is the Effective Energy relative to ANFO at a density of 0.85g/cc. ANFO has an effective energy of 2.3 MJ/kg.

2. VOD will depend on application including explosive density, blasthole diameter, temperature and degree of confinement. The minimum VOD quoted is based on unconfined test firing data and calculated energy values.

Solarprime MaxX is packaged in plastic film/ layflats. Each box contains nominally 25kg of product with standard cartridge sizes and counts as follows:

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 83 | 540 | 2780 | 9 |

Other diameter / grams combinations can be offered on request.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Solarprime MaxX is 6 Months from the date of Manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate pre-maturely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : Solarprime MaxX

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Permitted Explosives

Supercoal 1 is a detonator sensitive packaged emulsion explosive. The Director General of Mines safety (DGMS) has approved Supercoal 1 as a P1 type permitted explosive for use in Degree I gassy coal mines/seams. The emulsion has firm putty like consistency. It is plastic wrapped with steel wire end clips. Cartridges are identified individually as P1 Permitted explosive with a product name, cartridge dimensions and name of manufacturer printed on each cartridge.

Supercoal 1 is a water resistant packaged explosive for use in all applications that require the use of a P1 classified explosive.

| Nominal Density (g/cc) | 1.15 ± 0.05 |

| Relative Weight Strength* | 92 % |

| Relative Bulk Strength* | 130 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 +/- 0.4 |

*Compared to ANFO@ 0.85 g/cc

Packaging

Net Explosive weight is nominally 25 Kgs and standard cartridge sizes are as below :

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 32 | 180 | 150 | 166 |

| 32 | 200 | 200 | 125 |

Maximum energy of blasthole can be achieved by tamping the explosive with a wooden tamping rod.

Do Not use metal instrument to tamp explosives.

Do Not tamp primer cartridge containing a detonator.

The maximum charge per shot hole for P1 type permitted explosives must not exceed 800 grams in Degree I mines.

The recommended initiator for Supercoal 1 is a No. 6 strength, DGMS approved, non-incendive short delay detonator.

Detonating Cords are not recommended for use with Supercoal 1.

The post detonation fume characteristics and non incendivity of Supercoal 1 make it suitable for blasting in underground coal applications. User should ensure that adequate ventilation is provided prior to re-entry to the blast site

Avoid extremes of shock, heat, friction or mechanical impact to prevent pre-mature initiation.

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Supercoal 1 is 6 months from the date of manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate pre-maturely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SUPERCOAL 1

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Packaged SUPERCOAL 3 is a detonator sensitive emulsion explosive. The Director General of Mines safety (DGMS) has approved SUPERCOAL 3 as a P3 type permitted explosive for use in Degree I and II gassy coal mines/seams. The emulsion has firm putty like consistency. It is plastic wrapped with steel wire end clips. Cartridges are identified individually as P3 Permitted explosive with a product name, cartridge dimensions and name of manufacturer printed on each cartridge.

SUPERCOAL 3 is a water resistance packaged explosive for use in all applications that require the use of a P3 classified explosive.

| Nominal Density (g/cc) | 1.15 ± 0.05 |

| Relative Weight Strength* | 85 % |

| Relative Bulk Strength* | 115 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 +/- 0.4 |

*Compared to ANFO@ 0.85 g/cc

SUPERCOAL 3 packaging cases and film are labelled with SUPERCOAL 3. Net Explosive weight is nominally 25 Kgs and standard cartridge sizes

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 32 | 180 | 150 | 166 |

| 32 | 200 | 200 | 125 |

Maximum energy of blasthole can be achieved by tamping the explosive with a wooden tamping rod.

Do Not use metal instrument to tamp explosives.

Do Not tamp primer cartridge containing a detonator.

The maximum charge per shot hole for P3 type permitted explosives must not exceed 1000 grams in Degree I mines.

The recommended initiator for Supercoal 3 is a No. 6 strength, DGMS approved, non-incendive short delay detonator.

Detonating Cords are not recommended for use with Supercoal 3.

The post detonation fume characteristics and non incendivity of Supercoal 3 make it suitable for blasting in underground coal applications. User should ensure that adequate ventilation is provided prior to re-entry to the blast site

Avoid extremes of shock, heat, friction or mechanical impact to prevent pre-mature initiation.

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Supercoal 3 is 6 months from the date of manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate prematurely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SUPERCOAL 3

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Supercoal 5 is a detonator sensitive packaged emulsion explosive. The Director General of Mines safety (DGMS) has approved Supercoal 5 as a P5 type permitted explosive for use in Degree I, II and III gassy coal mines /seams.

The emulsion has firm putty like consistency. It is plastic wrapped with steel wire end clips. Cartridges are identified individually as P5 Permitted explosive with product name, cartridge dimensions and name of manufacturer printed on each cartridge.

Supercoal 5 is a water resistance packaged explosive for use in all applications that require the use of a P5 classified explosive.

| Nominal Density (g/cc) | 1.15 ± 0.05 |

| Relative Weight Strength* | 70 % |

| Relative Bulk Strength* | 95 % |

| Minimum Velocity of Detonation (Km/Sec) | 3.5 +/- 0.4 |

*Compared to ANFO@ 0.85 g/cc

Net Explosive Box weight is nominally 25 Kgs and standard cartridge sizes as below:

| Diameter mm |

Nominal length mm |

Nominal Mass gm |

Cartridge per Box |

| 32 | 180 | 150 | 166 |

| 32 | 200 | 200 | 125 |

Maximum energy of blasthole can be achieved by tamping the explosive with a wooden tamping rod.

Do Not use metal instrument to tamp explosives.

Do Not tamp primer cartridge containing a detonator.

The maximum charge per shot hole for P5 type permitted explosives must not exceed 1000 grams in Degree I mines and 565 grams in Degree II & III mines.

The recommended initiator for Supercoal 5 is a No.6 strength, DGMS approved, non-incendive short delay detonator.

Detonating Cords are not recommended for use with Supercoal 5.

The post detonation fume characteristics and non incendivity of Supercoal 5 make it suitable for blasting in underground coal applications. User should ensure that adequate ventilation is provided prior to re-entry to the blast site.

Avoid extremes of shock, heat, friction or mechanical impact to prevent pre-mature initiation.

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the shelf life of Supercoal 5 is 6 months from the date of manufacturing. However exposure to hot or cold extremes may cause the product to deteriorate prematurely.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SUPERCOAL 5

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The undamaged product may be charged and fired several days later in dry holes (provided the product remains within its recommended shelf life).

If the explosives packaging is damaged, the sleep-time in a blasthole is influenced by the extent of damage to the packaging and by the nature of any water present.

Seismic Explosives

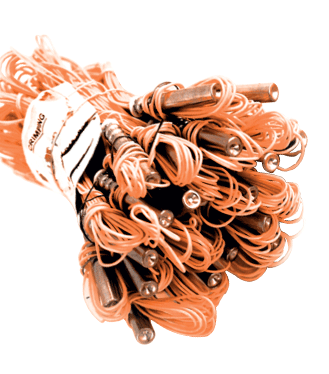

Superpower Seismic is a robust packaged emulsion explosive, specifically designed for seismic exploration. It is detonator sensitive, has high strength, high velocity of detonation and excellent water resistance.

The explosives are packed in rigid plastic couplable tubes. The rigid plastic cartridges with positive screw coupling give flexibility of charge size at the shot hole.

| Nominal Density (g/cc) | 1.20 +/- 0.05 |

| Hydrostatic Head | 60 m |

| Sleeping Time | 4 Weeks |

| Nominal Velocity of Detonation (unconfined) (Km/Sec) | 5 |

*Compared to ANFO@ 0.85 g/cc

Superpower Seismic is packaged in plastic tubes with product name & other details. Each Box contains 25kg of product.

| Diameter mm |

Length mm |

Weight ( kg) |

No. of Cartridges per Box |

| 50 | 330 | 0.5 | 50 |

| 50 | 580 | 1.0 | 25 |

| 63 | 225 | 0.5 | 50 |

| 63 | 380 | 1.0 | 25 |

| 63 | 655 | 2.0 | 12 |

| 63 | 810 | 2.5 | 10 |

| 76 | 315 | 1.0 | 25 |

| 76 | 450 | 2.0 | 12 |

| 76 | 625 | 2.5 | 10 |

Other diameter / grams combinations can be offered on request.

Connect tubes of Superpower Seismic by screwing them together, before they are inserted into the blast holes.

Avoid extremes of shock, heat, friction or mechanical impact to prevent pre-mature initiation.

Superpower Seismic should be handled and stored with care.

The undamaged product may be charged and fired several months later in dry holes (provided the product remains within its recommended shelf life).

A sleeping time upto 4 weeks is possible in wet holes.

Superpower Seismic has a storage life upto 12 months in an approved magazine, even in hot and humid conditions.

All regulations pertaining to the handling and use of such explosives apply.

Authorised Name of Explosive : SUPERPOWER SEISMIC

Proper Shipping Name : EXPLOSIVE, BLASTING, TYPE E

Class / Div. : 1.1D

UN No. : 0241

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. Please follow local regulations for the same and for any further information please contact Solar representative in your area.

Bulk Explosives

Low post Detonation fumes.

Excellent water resistance.

Easy handling and loading of holes.

Saves valuable time and manpower.

High VOD for better fragmentation.

Enhanced safety against impact and friction.

Product made to suit strata.

| PRODUCTS | SOLAR BE – 101 | SOLAR BE – 201 |

| VOD ( m/s ) | 4000 ± 500 | 4000 ± 500 |

| Density ( g / cc ) | 1.15 ± 0.05 | 1.15 ± 0.05 |

| Sensitivity | Booster Sensitivity (Sample will fire with 100 gm Cast – Booster ) |

Booster Sensitivity (Sample will fire with 100 gm Cast – Booster ) |

| Relative Bulk Strength ( As compared to ANFO ) |

125% | 130% |

| Total Energy / Kg | 860 Kcal/Kg | 890 Kcal/Kg |

| Viscosity | More than 40000 CPS ( Brookfield ) | More than 40000 CPS ( Brookfield ) |

| Compatibility / Water proofness |

Excellent Water Resistance | Excellent Water Resistance |

| Application | Suitable for large opencast mines operation. Charging is done in Shovel and Dragline deep holes from bottom to ensure water displacement | Suitable for large opencast mines operation. Charging is done in Shovel and Dragline deep holes from bottom to ensure water displacement |

| Sleeping Time | 10 Days | 10 Days |

These specification can be changed without any notice / intimation.

Low post Detonation fumes.

Excellent water resistance.

Easy handling and loading of holes.

Saves valuable time and manpower.

High VOD for better fragmentation.

Enhanced safety against impact and friction.

Product made to suit strata.

| PRODUCTS | SOLAR BE – 101 | SOLAR BE – 201 |

| VOD ( m/s ) | 4000 ± 500 | 4000 ± 500 |

| Density ( g / cc ) | 1.15 ± 0.05 | 1.15 ± 0.05 |

| Sensitivity | Booster Sensitivity (Sample will fire with 100 gm Cast – Booster ) |

Booster Sensitivity (Sample will fire with 100 gm Cast – Booster ) |

| Relative Bulk Strength ( As compared to ANFO ) |

125% | 130% |

| Total Energy / Kg | 860 Kcal/Kg | 890 Kcal/Kg |

| Viscosity | More than 40000 CPS ( Brookfield ) | More than 40000 CPS ( Brookfield ) |

| Compatibility / Water proofness |

Excellent Water Resistance | Excellent Water Resistance |

| Application | Suitable for large opencast mines operation. Charging is done in Shovel and Dragline deep holes from bottom to ensure water displacement | Suitable for large opencast mines operation. Charging is done in Shovel and Dragline deep holes from bottom to ensure water displacement |

| Sleeping Time | 10 Days | 10 Days |

These specification can be changed without any notice / intimation.

Low post Detonation fumes.

Excellent water resistance.

Easy handling and loading of holes.

Saves valuable time and manpower.

High VOD for better fragmentation.

Enhanced safety against impact and friction.

Product made to suit strata.

| PRODUCTS | SOLAR BE – UG – 909 |

| VOD ( m/s ) | 3800 ± 500 unconfined in 40 mm dia |

| Density ( g / cc ) | 1.15 ± 0.05 |

| Sensitivity | Booster Sensitivity (Sample will fire with 15 gm Cast – Booster ) |

| Relative Bulk Strength ( As compared to ANFO ) |

101 % Calculated |

| Total Energy / Kg | Above 550 Kcal / Kg ( Bubble Energy ) |

| Viscosity | More than 35000 CPS ( Brookfield ) |

| Compatibility / Water proofness | Excellent Water Resistance |

| Application | Suitable for Shaft sinking, tunneling, drift and raise development, room and pillar, mechanical cut and fill, VCR, upper retreat, bench and block caving |

| Sleeping Time | Minimum 03 Days |

| Loading Speed | 30 Kg to 80 Kg per minute |

| Viscosity | 35000 to 90000 CPS |

| Hose Length : | 40 m |

| Hose Diameter | 25 mm ( I.D ) and 31 mm O.D |

| Weight of Equipment | Approx 1500 Kg ( for 1200 Kg carrying capacity ) |

| Load Capacity | 1200 Kg 3 CHAMBER COMPARTMENT |

| Working Pressure | 3 BAR |

| Dimensions of machine | As per requirement |

| Safety Features | Low & High pressure trip, Temperature Trip, Rupture disc set at 6 BAR, Antistatic Hose and light weight |

| Hose Reel | Manual |

| Control System | PLC with control extension of console |

These specification can be changed without any notice / intimation.

Electronic Detonator

High Accuracy.

Programmable at Site.

Enhanced Safety.

| Parameters | |

| Shell Material | Alluminium / Copper |

| Strength | No.08 / No. 06 |

| Shell Length | 85 mm |

| Shell O.D. | 7.5 mm |

| Delay Range | 0 ms to 8000 ms |

| Max Operating Temp | 60°c |

| Water Resistance | Excellent |

| Leg Wire Material | Copper Coated Steel / Copper |

| Max Leg Wire Length | 60 Meters |

| Bus Bar Wire Material – (Resistance) | Copper, Two Coloured ( 0.07 /mtr.) |

| Max. Circuit Resistance | 100 ohms |

| Delay Time | ± 1ms upto 500 ms & ± 0.2 % above 500 ms |

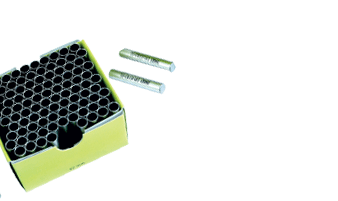

Non-Electric Detonator

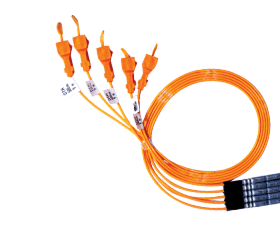

SUPREME DET-S Down The Hole assemblies provide short delay in the non-electric initiation system. Used in conjunction with detonating cord trunk lines or other Non-Electric delay systems to provide flexibility in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

The SUPREME DET-S Down The Hole is developed to be used in a wide range of temperature conditions.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for anything other than loading primer explosives. Never pull so hard to stretch or break shock tube – a premature detonation may result.

| PRODUCT | SUPREME DET-S Down the Hole Detonator (DTH) |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 200, 250, 300, 400, 450, 500 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

SUPREME DET-S Down the Hole Detonator assemblies are wound in regular coils and packed in anti static poly bags. These are packed in Fibre Board Boxes.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantity per Poly bags can vary as per customer requirement.

Shock Tube lengths above 100 m will be provided in spools.

SUPREME DET-S Down the hole Detonator assemblies are uni-directional. These can be used with Detonating Cord, another Surface Delay System.

SUPREME DET-S Down the hole Detonator is not designed toinitiate shock tube and detonating cord in the same block at the same time.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SUPREME DET-S Down the Hole Detonator is 2 years from the date of manufacture.

Authorised Name : Supreme Det S

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

SOLAR DET Down The Hole assemblies provide short delay in the non-electric initiation system. Used in conjunction with detonating cord trunk lines or other Non-Electric delay systems to provide flexibility in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

The SOLAR DET Down The Hole is developed to be used in a wide range of temperature conditions.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for anything other than loading primer explosives. Never pull so hard to stretch or break shock tube – a premature detonation may result.

| PRODUCT | SOLAR DET Down the Hole Detonator (DTH) |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 200, 250, 300, 400, 450, 500 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request. These specifications can be changed without any notice / intimation to buyer.

SOLAR DET Down the Hole Detonator assemblies are wound in regular coils and packed in anti static poly bags. These are packed in Fibre Board Boxes.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantity per Poly bags can vary as per customer requirement.

Shock Tube lengths above 100 m will be provided in spools.

SOLAR DET Down the hole Detonator assemblies are uni-directional. These can be used with Detonating Cord, another Surface Delay System.

SOLAR DET Down the hole Detonator is not designed toinitiate shock tube and detonating cord in the same block at the same time.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SOLAR DET Down the Hole Detonator is 2 years from the date of manufacture.

Authorised Name : SOLAR DET

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

SUPREME DET-S Long Period Detonator assemblies provide Long delay, non-electric initiation of underground blast patterns. Used in conjunction with detonating cord trunlines, SUPREME DET-S Long Period Detonator in 18 delay periods, provide flexibility in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

| PRODUCT | SUPREME DET-S Long Period Detonator (LDS) |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 300, 600, 900, 1200, 1500, 1900, 2300, 2700, 3100, 3500, 4000, 4500, 5000, 5500, 6000, 6500, 7000, 7500 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

SUPREME DET-S Long Period Detonator assemblies are wound in regular coils and packed in anti static poly bags. These are packed in Fibre Board Boxes.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantity per Poly bags can vary as per customer requirement.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SUPREME DET-S Long Period Detonator is 2 years from the date of manufacture.

Authorised Name : Supreme Det S

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

SOLAR DET Long Period Detonator assemblies provide Long delay, non-electric initiation of underground blast patterns. Used in conjunction with detonating cord trunlines, SOLAR DET Long Period Detonator in 18 delay periods, provide flexibility in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

| PRODUCT | SOLAR DET Long Period Detonator (LDS) |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 300, 600, 900, 1200, 1500, 1900, 2300, 2700, 3100, 3500, 4000, 4500, 5000, 5500, 6000, 6500, 7000, 7500 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for anything other than loading primer explosives. Never pull so hard to stretch or break shock tube a premature detonation may result.

SOLAR DET Long Period Detonator assemblies are wound in regular coils and packed in anti static poly bags. These are packed in Fibre Board Boxes.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantity per Poly bags can vary as per customer requirement.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SOLAR DET Long Period Detonator is 2 years from the date of manufacture.

Authorised Name : SOLAR DET

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

SUPREME DET-S Short Period Detonator assemblies provide short delay, non-electric initiation of underground blast patterns. Used in conjunction with detonating cord trunk lines, SUPREME DET-S Short Period Detonator in 20 delay periods, provide flexibility in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

| PRODUCT | SUPREME DET-S Short Period Detonator (SDS) |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 25, 50, 75, 100, 125, 150, 175, 200, 225, 250, 300, 350, 400, 450, 500, 600, 700, 800, 900, 1000 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for anything other than loading primer explosives. Never pull so hard to stretch or break shock tube a premature detonation may result.

SUPREME DET-S Short Period Detonator assemblies are wound in regular coils and packed in anti static poly bags. These are packed in Fibre Board Boxes.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantities in Poly bag may vary as per customer requirements

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SUPREME DET-S Short Period Detonator is 2 years from the date of manufacture.

Authorised Name : Supreme Det S

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

SOLAR DET Short Period Detonator assemblies provide short delay, non-electric initiation of underground blast patterns. Used in conjunction with detonating cord trunk lines, SOLAR DET Short Period Detonator in 20 delay periods, provide flexibility in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

| PRODUCT | SOLAR DET Short Period Detonator (SDS) |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 25, 50, 75, 100, 125, 150, 175, 200, 225, 250, 300, 350, 400, 450, 500, 600, 700, 800, 900, 1000 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for anything other than loading primer explosives. Never pull so hard to stretch or break shock tube a premature detonation may result.

SOLAR DET Short Period Detonator assemblies are wound in regular coils and packed in anti static poly bags. These are packed in Fibre Board Boxes.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantities in Poly bag may vary as per customer requirements

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SOLAR DET Short Period Detonator is 2 years from the date of manufacture.

Authorised Name : SOLAR DET

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

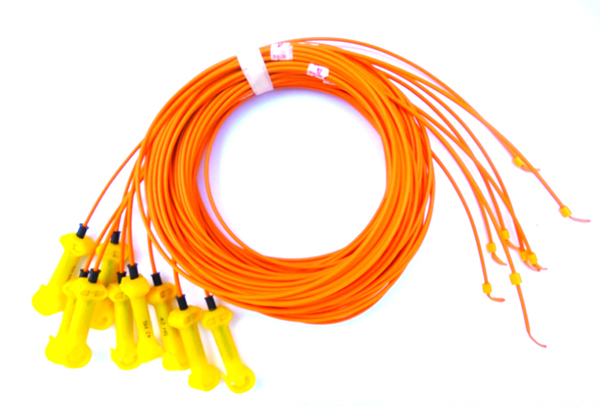

SUPREME DET-S Surface Detonator is a non-electric surface delay unit consisting of low energy millisecond delay detonator housed in plastic connector block.

SUPREME DET-S Surface Detonator is designed to provide surface delay in a non-electric blast pattern in quarries, surface coal operations, open pit mines and construction projects. These are used in conjunction with detonating cord down lines or other non-electric delay systems to provide flexibility in blast design and ease of use.

The SUPREME DET-S Surface Detonator is developed to be used in a wide range of temperature conditions.

| PRODUCT | SUPREME DET-S Surface Detonator (STL) |

| MOC of shell | Aluminium |

| Detonator strength | Not Applicable |

| Delay Timing, ms# | 17, 25, 42, 67, 100, 200 |

| Length of the shock tube | As per customers requirement |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube and Supreme Det-S Surface Detonator hooks have different colours for different delays. Company name is embossed on Block connector. |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

SUPREME DET-S Surface Detonator assemblies are uni-directional. These can be used with Detonating Cord, another Surface Delay System.

SUPREME DET-S Surface Detonator is not designed to initiate shock tube and detonating cord in the same block at the same time.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 2 | 20 | 360 |

| 4 | 10 | 260 |

| 5 | 10 | 220 |

| 6 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SUPREME DET-S Surface Detonator is 2 years from the date of manufacture.

Authorised Name : Supreme Det S

Shipping Name : DETONATOR ASSEMBLIES, NON – ELECTRIC for blasting

UN No. : 0360

Class / Div : 1.1B

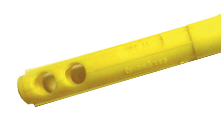

SOLAR DET Surface Trunk Line detonator consists of 3-Layered shocktube having internal coating of HMX compound & Detonator assembly which provides Surfce non-electric delay initiation of surface and underground blast patterns.Used in conjunction with detonating cord trunk lines or other Non-Electric delay systems provide flexibiity in blast design and ease of use. These can be used in surface or underground mines, at quarries or at construction projects.

The SOLAR DET Surface Trunk Line detonator is developed to be used in a wide range of temperature conditions. The product may be used in areas encountering high temperatures and cold conditions.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for any thing other than cast booster. Never pull so hard to stretch or break shock tube which may cause a premature detonation.

| PRODUCT | SOLAR DET Surface Trunk Line Detonator |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | 17, 25, 42, 67, 100, 200 |

| Length of the shock tube | As per customers requirement |

| Tube Coating | HMX Compound |

| Tube Coating (mg/mtr) | 15 ± 2 |

| VOD, (mtr/second) | 2000 ± 200 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube. E mark at bottom of shell and “SOLAR” embossed on plastic connector. Different coloured connectors for different delay timings |

| Water Resistance | Excellent |

| Packing | Depending on length, No. of Detonators are packed in antistatic polybags and such polybags are kept in approved fibre board case. A barcode sticker having details such as shock tube length, type and delay numbers etc. is pasted on the fibre board box. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

SOLAR DET Surface Trunk Line detonator assemblies are wound in regular coils and packed in antistatic polybags.These are shipped in Fibre Board cases.

SOLAR DET Surface Detonator assemblies are wound in regular coils and packed in antistatic polybags. These are packed in Fibre Board cases.

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 18 | 5 | 70 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantity in Polybags may vary as per customer requirement.

Shock Tube lengths above 100 mtrs will be provided in spools.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SOLAR DET Surface Trunk Line detonator is 2 years from the date of manufacture.

Class / Div : 1 / 1.1

Group : B

UN No. : 0360

SUPREME DET-S Combidet detonator are signal tube based detonator, combining In-hole delay with a Surface delay detonator. It consists of 3-Layered shocktube, having internal coating of HMX compound & delay detonator crimped to each end which provides non-electric delay initiation of surface and underground blast patterns.

The SUPREME DET-S Combidet detonator is developed to be used in a wide range of temperature conditions. The product may be used in areas encountering high temperatures and cold conditions.

Avoid damage to the shock tube. Do not use shock tube as a lowering line for any thing other than cast booster. Never pull so hard to stretch or break shock tube which may cause a premature detonation.

VOD, (mtr/second)2000 ± 200

| PRODUCT | SUPREME DET-S COMBI-DET |

| MOC of shell | Aluminium |

| Detonator strength | No. 8 / No.8* |

| Delay Timing, ms# | Surface (ms)17, 25, 42, 67, 100, 200 In Hole (ms) 200, 250, 300, 350, 400, 450, 500 |

| Length of the shock tube | As per customers requirement |

| Tube Coating | HMX Compound |

| Coating Qty. (mg/mtr) | 15 ± 2 |

| Tensile strength | 30 kgf (min) |

| Identification mark | Delay timing and length stickers tagged with each shock tube. E mark at bottom of shell and “EEL” embossed on plastic connector. And STL hooks having different colour for different delays are used.“Danger Explosives-EEL” printed on shell. |

| Water Resistance | Excellent |

| Packing | Depending on length, No.of Detontors are packed in anti-static Poly bags and kept in approved fibre board boxes. A barcode sticker having details such as shock tube length, type and delay Numbers/Time is pasted on the boxes. |

#Specific delay period also available on request.

These specifications can be changed without any notice / intimation to buyer.

SUPREME DET-S Combidet Detonator assemblies are wound in regular coils and packed in anti-static polybags.These are shipped in Fibre Board cases.

18570

| Length ( in Mtrs ) |

No. Per Polybag |

Qty. Per Box |

| 3.5 | 10 | 280 |

| 5.0 | 10 | 220 |

| 6.0 | 10 | 180 |

| 9 | 10 | 140 |

| 12 | 5 | 110 |

| 15 | 5 | 90 |

| 24 | 5 | 50 |

Specific lengths and Delay Timings can be made available on request.

Quantity per Poly bags can vary as per customer requirement.

Shock Tube lengths above 100 m will be provided in spools.

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of SUPREME DET-S Combi-Det Detonator is 2 years from the date of manufacture.

Authorised Name : Supreme Det S

Class / Div : 1/1.1

Group : B

UN No. : 0360

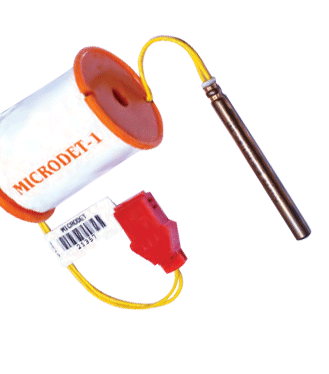

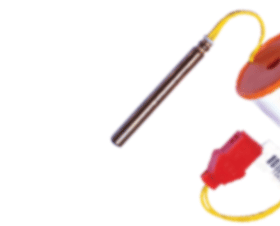

Electric Detonator

The Electric Seismic detonator is an initiator system of explosive charge that can convert an electric into a detonation.

The special configuration of the metallic filament used to manufacture the Seismic Electric Detonator results in low resistance which assures effective high initiation energy. The property of the filament makes it safer in terms of its functionality when compared to other detonators available in the market.

The electric detonator has an electro-pyrotechnical element that can react in less than 1.0 millisecond between the moment required current is applied and detonation takes place. The electro-pyrotechnical element is hosted in an antistatic device. The interior design of the detonator that includes the insensitive electro-pyrotechnical set and the antistatic plug was specially developed to prevent accidental detonation associated with static or erratic electricity.

The Aluminium detonator shell contains a base charge of PETN and Primary Charge of Lead Azide, Lead Styphnate & Aluminium powder. The total amount of explosives in the detonator including primary charge is less than 1 g.

Product would be with copper wire of 0.6 mm diametre. The insulation over copper wire is PE. Lead wire colour can be given any colour preferred by the client.

| Identification Mark | EEL mark on plug |

| Class | I |

| Shell Length | 56 mm |

| MOC of Shell | No 8 |

| Secondary Charge | PETN |

| Type | Instantaneous |

| Wire Length | as per customer req. |

| Wire Colour* | Yellow (twin) |

| Wire Material | Copper |

| Wire Resistance | 0.05-0.07ohms/Mtr (Cu) |

| Series Firing Current | 5 A for 4 ms |

| No Firing Current | 0.45 Amp for 5 mins |

| Min Single Fire Current | 2.5 A for 4 ms |

| Fusehead Resistance | 0.45 to 0.6 ohms |

| Use Temperature | -20 deg C to 60 deg C |

| Water Resistance | Excellent |

| Resistance to Hydraulic Pressure | 3 Kgs for 48 Hours |

| Insensitivity to Impact | 2 Kgs drop from a height of 0.4 Mtr |

| Response Time | Max 1 ms at 5 A |

| Tensile Strength | 145 – 150 N/mm2 |

| Drop Test | 5 Mtrs height |

| Jolt Test | 60 Jolts/min from 150mm height for 30 minutes |

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Packet |

Gross Wt. |

Net Wt. |

| 3 Mtr | 400 | 10 | 10 | 13.5 | 11 |

| 6 Mtr | 250 | 10 | 10 | 17 | 14.5 |

| 8 Mtr. | 250 | 05 | 05 | 23 | 20.5 |

| 10 Mtr. | 100 | – | – | 13.5 | 11 |

| 12 Mtr. | 100 | – | – | 15.5 | 13 |

| 15 Mtr. | 100 | – | – | 19 | 16.5 |

| 25 Mtr | 64 | – | – | 16.5 | 14 |

| 30 Mtr. | 64 | – | – | 19 | 16.5 |

| 35 Mtr. | 36 | – | – | 13 | 10.5 |

| 40 Mtr. | 36 | – | – | 14.5 | 12 |

| 45 Mtr. | 36 | – | – | 16 | 13.5 |

| 50 Mtr. | 36 | – | – | 17.5 | 15 |

*as per customers request, any length of lead wire can be supplied.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of Supreme Seismic Det is 2 years from the date of manufacture.

Authorised Name of Explosive : Electric Seismic Detonators

Proper Shipping Name : DETONATORS, ELECTRIC for Blasting

Class / Div. : 1.1B

UN No. : 0030

Supreme Copper Electric detonators meant for use in underground coal mines.

Supreme CED and Supreme CSDD detonators have primary charge of Lead Azide / Lead Styphnate in case of CED and Lead Azide / Aluminium Powder in case of CSDD, and base charge in both is PETN. In CSDD, the detonation is pyrotechnically delayed at a predetermined time after the firing pulse is applied.

Supreme CSDD provide delay flexibility in short period blast design, the accurate delay timing allows for a wider variety of blast design possibilities.

# Other lead wire colour can be given on request.

| CED | CSDD | |

| Identification Mark | EEL mark on plug | EEL mark on plug |

| Type | Instantaneous Detonator | Short Delay Detonator |

| Shell Length | 42 mm | 42-60 mm |

| MOC of Shell | No 8 | No 8 |

| Wire Length | As per customer | As per customer |

| Wire Colour# | Light Green | Red + White |

| Wire Material | Cu or GI | Cu or GI |

| Wire Resistance Cu | 0.05 – 0.07, Ohms / Mtr | 0.05 – 0.07, Ohms / Mtr |

| Wire Resistance GI | 0.05 – 0.07, Ohms / Mtr | 0.05 – 0.07, Ohms / Mtr |

| Series Firing Current | 1.2 A for 4 ms | 1.2 A for 4 ms |

| All Firing Impulse | 2.5 mJ | 2.5 mJ |

| No Firing Current | 0.18 A for, 5 minutes | 0.18 A for, 5 minutes |

| Minimum Single Fire Current | 0.8 A for 4 ms | 0.8 A for 4 ms |

| Fusehead Resistance | 1.6 to 2.0 ohms | 1.6 to 2.0 ohms |

| Use Temperature | -20 deg C to 60 deg C | -20 deg C to 60 deg C |

| Water Resistance | Excellent | Excellent |

| Resistance to Hydraulic Pressure | 3 Kgs for 48 Hours | 3 Kgs for 48 Hours |

| Insensitivity to | 2 Kgs drop from | 2 Kgs drop from |

| Impact | height of 0.4 Mtr | height of 0.4 Mtr |

| Drop Test | from 5m height | from 5m height |

| Jolt Test | 60 Jolts/min from 150mm height for 30 minutes | |

PACKING ( CED ) GI Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 1.8 Mtr. | 1500 | 25 | 50 | 20 | 18 |

| 2.0 Mtr. | 1000 | 25 | 50 | 15 | 13 |

| 2.5 Mtr. | 1000 | 25 | 50 | 23 | 21 |

PACKING ( CSDD ) GI Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 2.5 Mtr. | 1000 | 25 | 50 | 22 | 20 |

| 3.0 Mtr. | 750 | 25 | 25 | 20 | 18 |

PACKING ( CED ) CU Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 1.8 Mtr. | 1000 | 25 | 50 | 18 | 16 |

| 2.0 Mtr. | 1000 | 25 | 50 | 20 | 18 |

| 2.5 Mtr. | 750 | 25 | 50/td> | 18 | 16 |

PACKING ( CSDD ) CU Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 2.5 Mtr. | 750 | 25 | 50 | 22 | 20 |

| 3.0 Mtr. | 750 | 25 | 25 | 22 | 20 |

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Authorised Name of Explosive : ELECTRIC DETONATOR

Proper Shipping Name : DETONATORS, ELECTRIC for Blasting

Class / Div. : 1.1B

UN No. : 0030

Supreme AED-Ultra Safe is designed to enhance safety in handling as compared to conventional Aluminium Instantaneous Electric Detonators by removal of most hazardous and sensitive lead styphnate and also makes the product environment friendly.

It provides instantaneous detonation of explosive or detonating cord in quarries, surface operations, open pit mines and construction projects.

Drop Testfrom 5 mtr height

| Identification Mark | EEL mark on plug |

| Shell Length | 42 mm |

| MOC of Shell | No 8 |

| Detonator Strength* | No 8 |

| Secondary Charge | PETN |

| Type | Instantaneous |

| Wire Length | as per customer req. |

| Wire Colour | Orange |

| Wire Material | GI / Copper |

| Wire Resistance | 0.05-0.07ohms/Mtr (Cu), 0.5-0.7 ohms / Mtr (GI) |

| Series Firing Current | 1.2 A, 4 m Sec |

| All Firing Impulse | 2.5 MJ |

| No Firing Current | 0.18 A for 5 Mins |

| Min Single Fire Current | 0.8 A for 4 ms |

| Fusehead Resistance | 1.6 to 2.0 ohms |

| Use Temperatur | -20 deg C to 60 deg C |

| Water Resistance | Excellent |

| Resistance to Hydraulic Pressure | 3 Kgs for 48 Hours |

| Insensitivity to Impact | 2 Kgs drop from a height of 0.4 Mtr |

| Jolt Test | 60 Jolts/min from 150mm height for 30 minutes |

# Other lead wire colour can be given on request.

No. 8* is available on request.

GI Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Packet |

Gross Wt. |

Net Wt. |

| 1.5 Mtr | 1500 | 25 | 50 | 16 | 14 |

| 1.8 Mtr. | 1500 | 25 | 50 | 18 | 16 |

| 2 Mtr. | 1000 | 25 | 50 | 14 | 12 |

| 3.0 Mtr | 1000 | 25 | 25 | 19 | 17 |

Copper Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Packet |

Gross Wt. |

Net Wt. |

| 1.5 Mtr | 1000 | 25 | 50 | 14.5 | 12.5 |

| 1.8 Mtr. | 1000 | 25 | 50 | 17 | 15 |

| 2 Mtr. | 1000 | 25 | 50 | 18 | 16 |

| 3.0 Mtr | 750 | 25 | 25 | 19 | 17 |

For the best results, store under moderate temperatures and dry conditions in a well ventilated, approved detonator magazine.

If stored in cool, dry, well ventilated magazine and handled properly, the maximum shelf life of Supreme AED Ultra Safe is 3 years from the date of manufacture.

Authorised Name of Explosive : SUPREME AED ULTRA SAFE

Proper Shipping Name : DETONATORS, ELECTRIC for Blasting

UN No. : 0030

Class / Div. : 1.1B

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Solar Copper Electric detonators meant for use in underground coal mines.

Solar CED and Solar CSDD detonators have primary charge of Lead Azide / Lead Styphnate in case of CED and Lead Azide / Aluminium Powder in case of CSDD, and base charge in both is PETN.

In CSDD, the detonation is pyrotechnically delayed at a predetermined time after the firing pulse is applied. Solar CSDD provide delay flexibility in short period blast design, the accurate delay timing allows for a wider variety of blast design possibilities.

| CED | CSDD | |

| Identification Mark | SIIL mark on plug | SIIL mark on plug |

| Type | Instantaneous Detonator | Short Delay Detonator |

| Shell Length | 42 mm | 42-60 mm |

| MOC of Shell | Copper | Copper |

| Detonator Strength | No. 8 | No. 8 |

| Wire Length | As per customer | As per customer |

| Wire Colour# | Light Green | Red + White |

| Wire Material | Cu or GI | Cu or GI |

| Wire Resistance Cu | 0.05 – 0.07, Ohms / Mtr | 0.05 – 0.07, Ohms / Mtr |

| Wire Resistance GI | 0.05 – 0.07, Ohms / Mtr | 0.05 – 0.07, Ohms / Mtr |

| Series Firing Current | 1.2 A for 4 ms | 1.2 A for 4 ms |

| All Firing Impulse | 2.5 mJ | 2.5 mJ |

| No Firing Current | 0.18 A for, 5 minutes | 0.18 A for, 5 minutes |

| Minimum Single Fire Current | 0.8 A for 4 ms | 0.8 A for 4 ms |

| Fusehead Resistance | 1.6 to 2.0 ohms | 1.6 to 2.0 ohms |

| Use Temperature | -20 deg C to 60 deg C | -20 deg C to 60 deg C |

| Water Resistance | Excellent | Excellent |

| Resistance to Hydraulic Pressure | 3 Kgs for 48 Hours | 3 Kgs for 48 Hours |

| Insensitivity to | 2 Kgs drop from | 2 Kgs drop from |

| Impact | height of 0.4 Mtr | height of 0.4 Mtr |

| Drop Test | from 5m height | from 5m height |

| Jolt Test | 60 Jolts/min from 150mm height for 30 minutes | |

# Other lead wire colour can be given on request.

PACKING ( CED ) GI Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 1.8 Mtr. | 1500 | 25 | 50 | 20 | 18 |

| 2.0 Mtr. | 1000 | 25 | 50 | 15 | 13 |

| 2.5 Mtr. | 1000 | 25 | 50 | 23 | 21 |

PACKING ( CSDD ) GI Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 2.5 Mtr. | 1000 | 25 | 50 | 22 | 20 |

| 3.0 Mtr. | 750 | 25 | 25 | 20 | 18 |

PACKING ( CED ) CU Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 1.8 Mtr. | 1000 | 25 | 50 | 18 | 16 |

| 2.0 Mtr. | 1000 | 25 | 50 | 20 | 18 |

| 2.5 Mtr. | 750 | 25 | 50/td> | 18 | 16 |

PACKING ( CSDD ) CU Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Wrapping |

Gross Wt. |

Net Wt. |

| 2.5 Mtr. | 750 | 25 | 50 | 22 | 20 |

| 3.0 Mtr. | 750 | 25 | 25 | 22 | 20 |

The disposal of explosives material is dangerous and require special training. Methods used for safe disposal may vary from case to case and will depend upon conditions under which the operations take place. For further information please contact Solar representative in your area.

Authorised Name of Explosive : ELECTRIC DETONATOR

Proper Shipping Name : DETONATORS, ELECTRIC for Blasting

Class / Div. : 1.1B

UN No. : 0030

The Aluminium Instantaneous Electric Detonator is an initiating system of explosives charge that can convert an electric impulse into a detonation. The Aluminium detonator shell contains a base charge of PETN and Primary Charge of Lead Azide, Lead Styphnate & Aluminium powder.

The Aluminium Instantaneous Electric Detonator is designed to provide instantaneous detonation of explosive or detonating cord in quarries, surface operations, open pit mines and construction projects.

Drop Testfrom 5 mtr height

| Identification Mark | SIIL mark on plug |

| Shell Length | 42 mm |

| MOC of Shell | No 8 |

| Detonator Strength* | No 8 |

| Type | Instantaneous |

| Wire Length | as per customer req. |

| Wire Colour | Pista Green |

| Wire Material | GI / Copper |

| Wire Resistance | 0.05-0.07ohms/Mtr (Cu), 0.5-0.7 ohms / Mtr (GI) |

| Series Firing Current | 1.2 A, 4 m Sec |

| All Firing Impulse | 2.5 MJ |

| No Firing Current | 0.18 A for 5 Mins |

| Min Single Fire Current | 0.8 A for 4 ms |

| Fusehead Resistance | 1.6 to 2.0 ohms |

| Use Temperatur | -20 deg C to 60 deg C |

| Water Resistance | Excellent |

| Resistance to Hydraulic Pressure | 3 Kgs for 48 Hours |

| Insensitivity to Impact | 2 Kgs drop from a height of 0.4 Mtr |

| Jolt Test | 60 Jolts/min from 150mm height for 30 minutes |

# Other lead wire colour can be given on request.

No. 8* is available on request.

GI Wire

| Length | Qty./ Case |

Qty./ Bundle |

Qty./ Packet |

Gross Wt. |

Net Wt. |

| 1.5 Mtr | 1500 | 25 | 50 | 16 | 14 |

| 1.8 Mtr. | 1500 | 25 | 50 | 18 | 16 |